整機質保一年,終身維護,

整機質保一年,終身維護,

定制特殊產品和非標自動化工作臺。

數十道監控管理流程。

<strike id="a44om"></strike>

Hardware mold high speed die cutting machine

(ZCCE01B - 00)

1. Equipment description:

1.1 equipment profile:

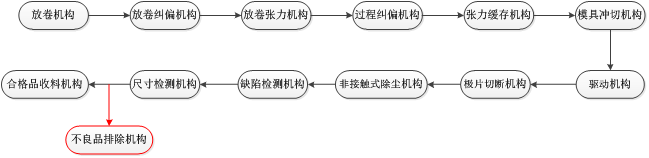

This equipment completes the lamination type lithium ion battery pole metal mold slicing process, the continuous coil material is cut into a single pole. Artificial roll pole rolling inflatable shaft installed to the device, the device automatically put volume, rectifying mechanism of rolling process to carry on the automatic adjustment, and control the tension of pole piece through the tension control system, servo mechanism will be transported to the sheet metal die cutting station, hardware die will be extremely ear and arc Angle cutting forming, cutting location with a cutting knife for sheet cutting into single pole piece, then to dust removal of single pole piece, through CCD detection plate surface quality and dimension, bad product has been dropped into the waste box, non-conforming material was sent to the material collecting box.

1.2 workflow:

1.3 system structure composition and description:

The serial number | Component name | The number of | instructions |

1 | Frame module | 1 | Provide support and installation reference for equipment |

2 | Rolling component | 2 | The material coil is fixed by inflatable shaft, with automatic rectifying function |

3 | Connect with the component | 1 | Convenient manual connection |

4 | Transition roll assembly | 1 | Including tension, process correction, transition roll and other components |

5 | Hardware die cutting components | 2 | The pole ear and chamfering are formed by metal die cutting |

6 | Drive component | 2 | Traction pole sheet for roll drive |

7 | Tension cache component | 1 | Cache 2 sets of drive mechanisms between the poles |

8 | Cut off the components | 1 | Cut a continuous pole into a single pole |

9 | Pole transport assembly | 1 | Transfer the pole from the cutter to the blanking position |

10 | Non-contact dust removal kit | 1 | The dust on the upper and lower sides of a single pole sheet can be removed by means of removing static electricity and air knife |

11 | CCD defect detection component | Detect upper and lower surface defects of the pole sheet | |

12 | CCD dimension detection component | 1 | Check the dimension of the pole |

13 | Receiving components | 1 | Collect qualified pole sheet and eliminate bad pole sheet |

14 | shield | Provide a relatively sealed environment for the equipment, with access control function | |

15 | Control system | 1 | Motion controller control, touch screen and button operation |

1.4 external dimensions of the equipment:

Overall size (mm) : length * width * height 7500*1780*2395 (including protective cover and vacuum cleaner)

Equipment weight: 6500KG